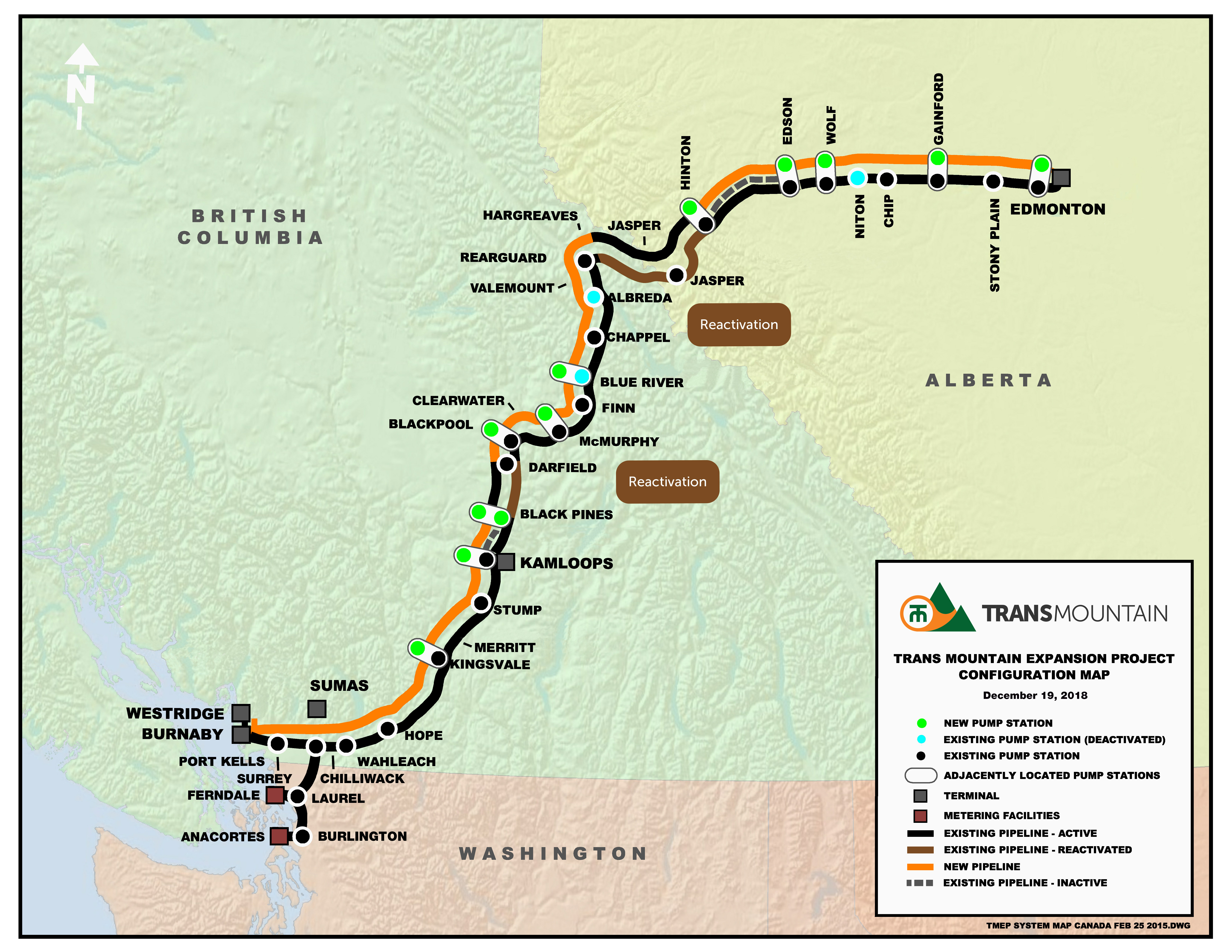

The Transmountain Pipeline Systems (TMX) spans from Edmonton, Alberta to Burnaby in British Columbia with approximately 1,150km of new and existing pipeline. The pipeline system accounting for pipeline, pump stations and terminal tanks is of prime interest from the standpoint of economic operations, safe transport accounting for leak detection, leak prevention and pipeline monitoring. This most important western Canada operating facility is of interest to academia and practitioners interested in improving operations and safety.

- Pressure, velocity, mass flow rate, temperature along the pipeline:

- Steady-state;

- Transient conditions;

- Integration of pump station operations with the pipeline operations:

- Pump curve;

- Discharge and suction pressures ;

- Leak monitoring by detection and leak localization;

- Equipment condition monitoring;

- Transient equations \begin{array}{c} \dfrac{\partial P}{\partial t}+V\dfrac{\partial P}{\partial x}+\rho a^2\dfrac{\partial V}{\partial x}=0 \\ \dfrac{\partial V}{\partial t}+\dfrac{1}{\rho }\dfrac{\partial P}{\partial x}+V\dfrac{\partial V}{\partial x}=-g\sin{\alpha} -\dfrac{\lambda }{2D}V\left | V \right| \\ \dfrac{\partial T}{\partial t}+\dfrac{T}{\rho C}\left ( \dfrac{\partial P}{\partial T} \right )_\rho \dfrac{\partial V}{\partial x}+V\dfrac{\partial T}{\partial x}=\lambda \dfrac{\left | V \right |^3}{2DC}-\dfrac{4K}{\rho DC}\left ( T-T_0 \right ) \end{array}

- Steady state equations \begin{array}{c} V\dfrac{d P}{d x}+\rho a^2\dfrac{d V}{d x}=0\\ \dfrac{1}{\rho }\dfrac{d P}{d x}+V\dfrac{d V}{d x}=-g\text{sin}\alpha -\dfrac{\lambda }{2D}V\left | V \right |\\ \dfrac{T}{\rho C}\left ( \dfrac{\partial P}{\partial T} \right )_\rho \dfrac{d V}{d x}+V\dfrac{d T}{d x}=\lambda \dfrac{\left | V \right |^3}{2DC}-\dfrac{4K}{\rho DC}\left ( T-T_0 \right ) \end{array}

The important monitoring issue of batch tracking in operations is resolved with the highest accuracy and provides an additional view of operations and scheduling. This is of importance when two vendors need to separate their commodities being transported and not mixed along the pipeline transport. The schematics of the TMX Segment 2 is shown in the picture. Assuming 3 commodities are being transported sequentially from Stony Plain Station to Hinton Station at varying flow rates. Our package can provide real-time information on batch location and volume, as well as the estimated time of arrival at the specific station.